Furnaces

Furnaces

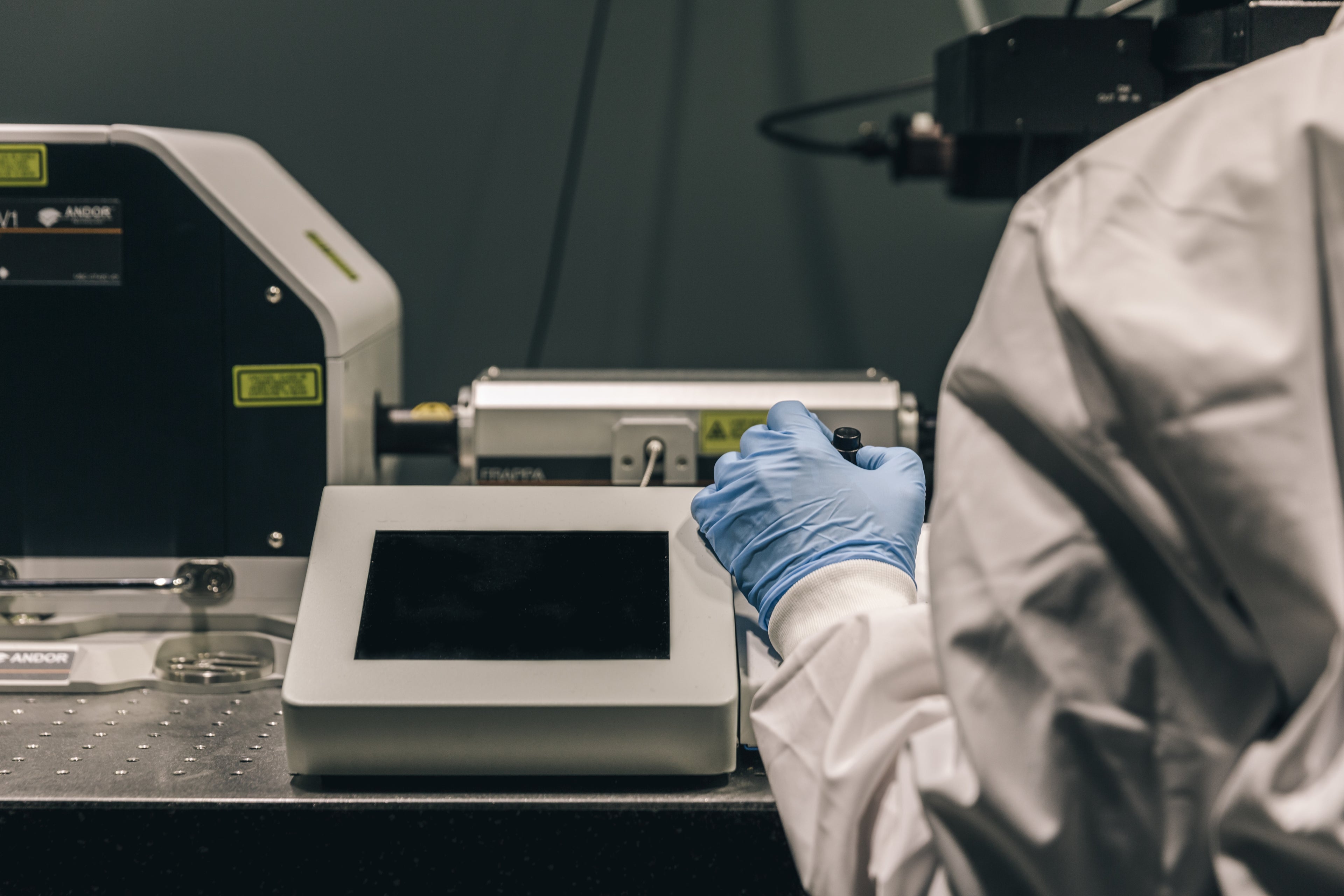

Precise results, uniform heat distribution, efficiency

✅ High-Temperature Precision

Our furnaces operate at up to 1600°C, with excellent thermal control for consistent, even sintering. Achieve perfect results without deformation or cracking.

✅ Fast & Flexible Firing Cycles

Optimized programs allow fast sintering for increased productivity, without compromising material quality or aesthetics.

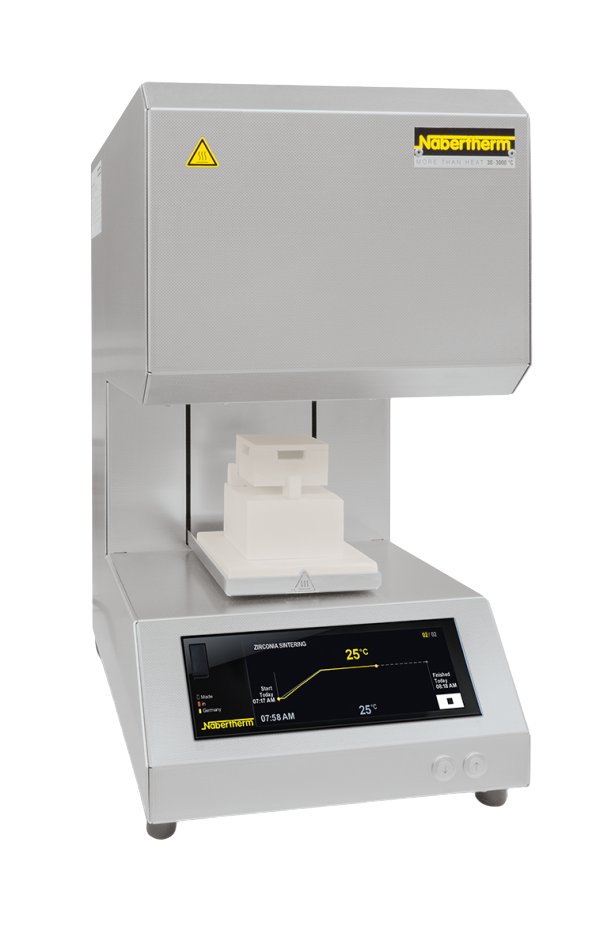

✅ User-Friendly Interface

Equipped with intuitive touchscreen controls and customizable programs, our units make operation simple—even for complex firing schedules.

✅ Energy-Efficient Performance

Advanced insulation and energy-saving technologies reduce power consumption while maintaining peak performance.

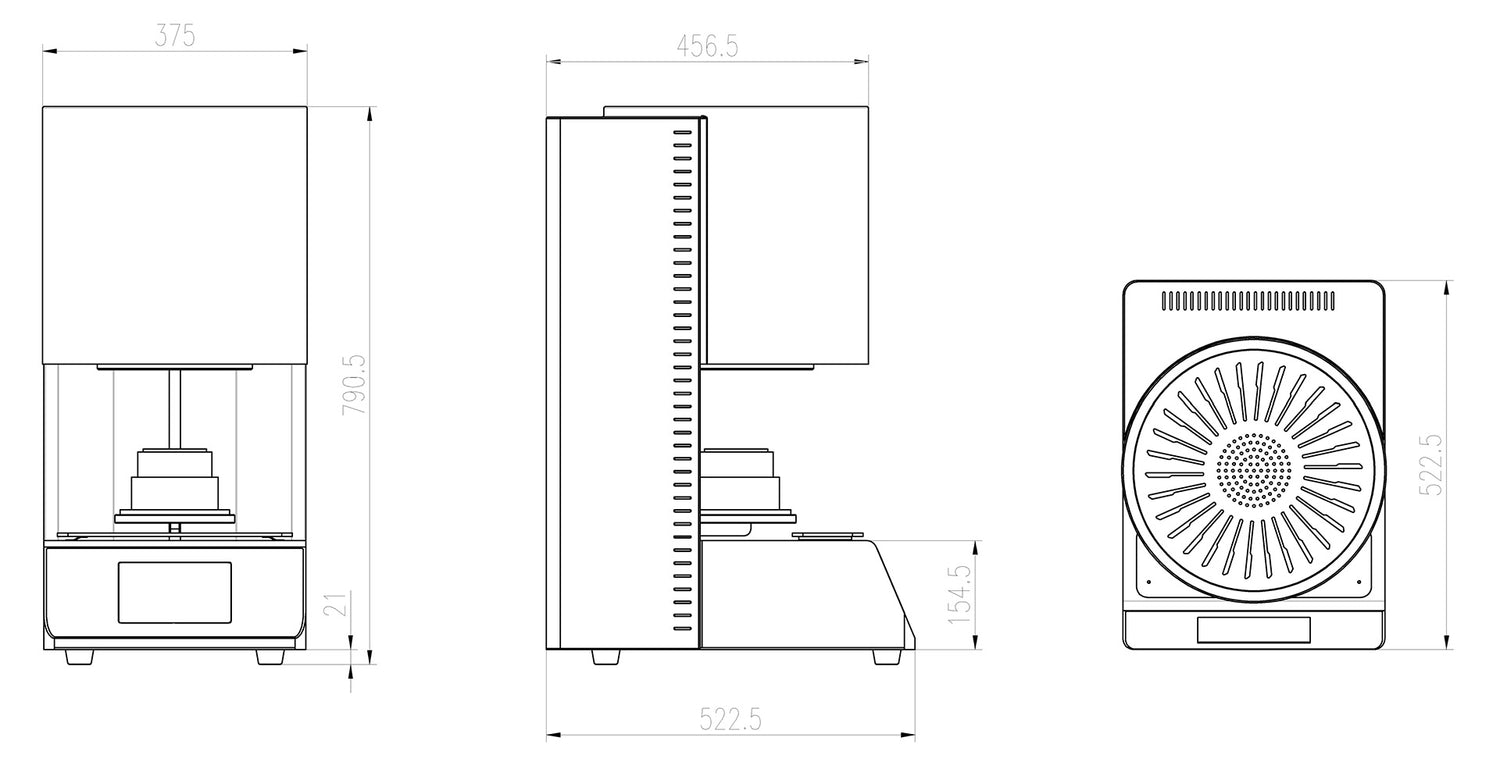

✅ Compact & Lab-Ready Design

Designed with the modern dental lab in mind, our furnaces are compact, quiet, and easy to integrate into any workspace.

High-temperature processing of zirconia

Our advanced sintering furnaces are designed for the high-temperature processing of zirconia restorations.

With intuitive controls, fast heating cycles, and uniform temperature distribution, they deliver reliable, high-quality results for crowns, bridges, and full-arch restorations. Perfect for modern dental labs seeking speed, accuracy, and consistency.

Efficiency. Precision. Reliability.

Take your dental lab to the next level with our state-of-the-art sintering furnaces, designed specifically for zirconia-based restorations. Whether you’re producing single crowns or full-arch frameworks, our furnaces ensure outstanding strength, translucency, and dimensional stability in every result.