LABVISION NX 350 Dry Mill

LABVISION NX 350 Dry Mill

Couldn't load pickup availability

Dry milling for Zirconia, with 5 axes

The NX 350 milling machine is specially built from cast iron, making the unit heavier but also more stable during milling, making it ideal for laboratories.

-

Advantages

Milling of anterior teeth at 90 degrees with the C-clamp for aesthetic restorations, down to a thin veneer of 0.2 mm. - Simultaneous 5-axis milling ensures excellent milling quality and more detailed results on the buccal side of the teeth.

With the dry lab machine, the best-selling 5-axis milling machine, you can mill a wide range of materials and various indications such as crowns and bridges, copings, inlays/onlays, veneers (as thin as 0.2 mm), implant bridges (All-on-4 or All-on-6 bridges), screw-retained crowns, etc.

Technical specifications

Technical specifications

Axes: 5-Axis

Dimensions: 520×560×720mm

Tool magazine capacity: 6 tools

Voltage: 220V

Spindle power: 0.8kW

Total power: 2.6kW

Spindle cooling: Air-cooled

Weight: 108kg

Milling type: Dry

Spindle speed: 3,000-40,000rpm

Materials: Zirconia, wax, PMMA, PEEK, HPP, etc.

Travel: X/Y/Z axis 165.5/108/93mm, A axis: 360˚, B axis: -28˚ ~ +92˚

Powerful Spindle

With a powerful 0.8kW spindle and servo motors, you can mill any dental material such as zirconia, PMMA, PEEK, wax, HPP, etc.

Tools Designed for Perfection

The tools are designed to enhance milling performance. By using the special tools from Jiny Dental, you can achieve the best milling results for all restorations.

Characteristics:

Simultaneous 5-axis milling

Aesthetic milling of anterior teeth at 90 degrees

Optional zero-point clamping system

Milling of all major materials used in the dental laboratory

B-axis tilting angle up to (-28) ~ (+92)°

Tool magazine for 6 tools

High-frequency spindle up to 40,000 rpm

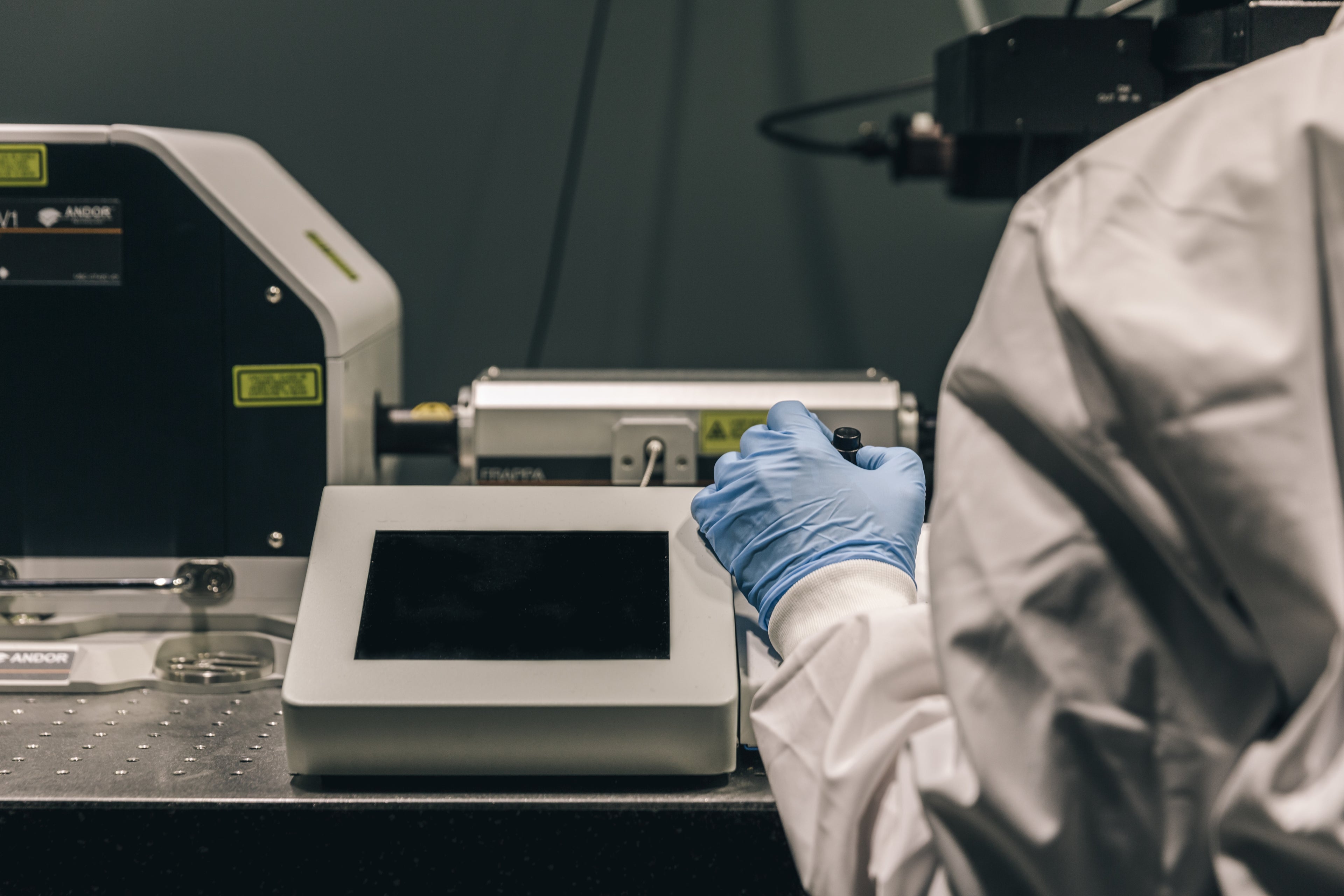

Integrated control with touchscreen

Servo motors on all axes

Tool magazine protection