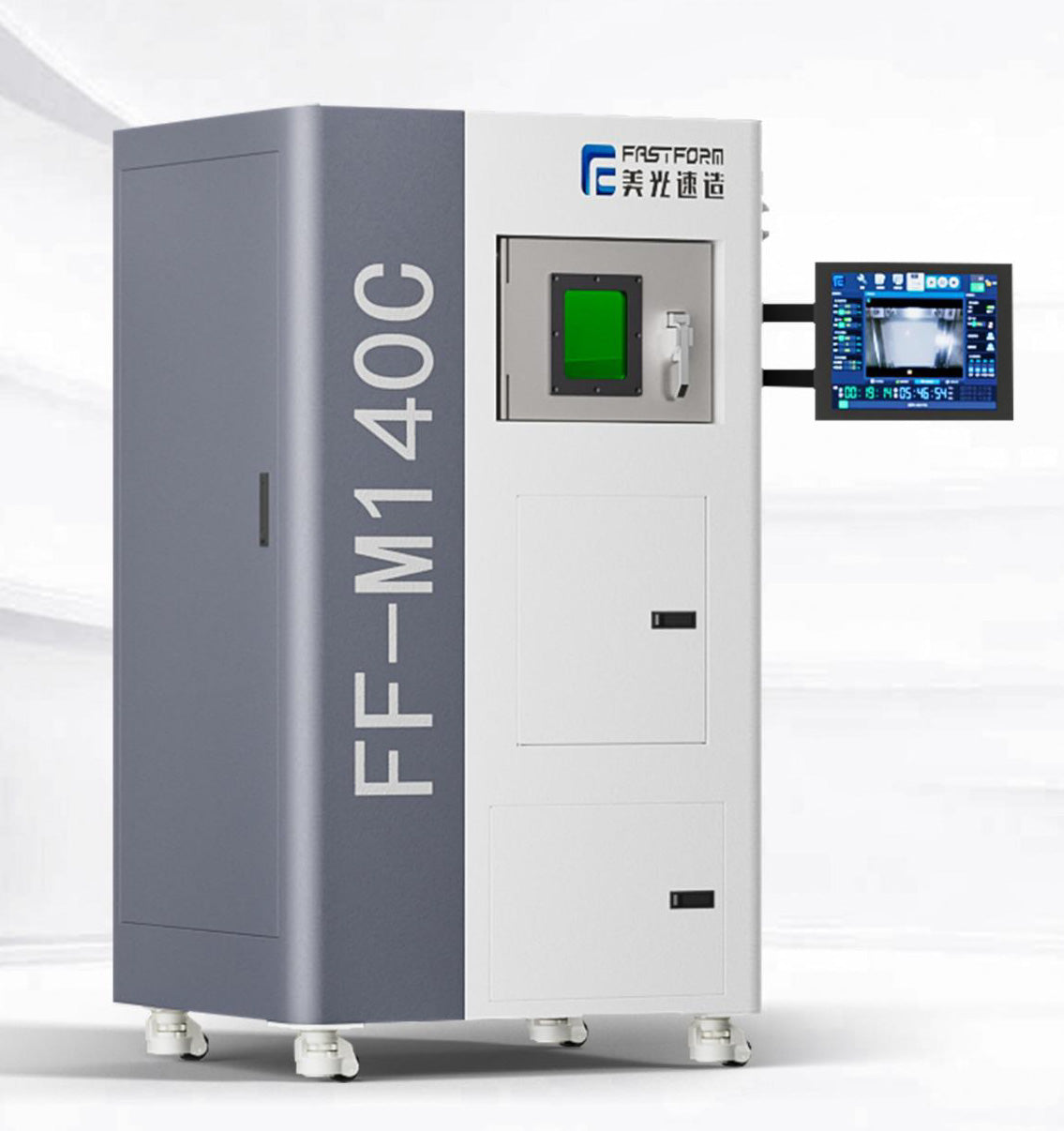

Laser sintering machine FastForm FF-M140C

Laser sintering machine FastForm FF-M140C

- Anti-reflection technology for direct printing on highly reflective materials such as copper

- Built-in camera for remote monitoring and operation

- Permanent filter, no need to replace the filter element

- Top-loading powder supply, no reservoir required, powder can be added during the printing process

Technical specifications

Technical specifications

Printing volume: 140mm diameter, 100mm height (circular)

Spot size: 50-80 µm

Powder layer thickness: 0.02-0.15 mm

Wiper type: flexible wiper

Number of lasers: 1

Laser power: 500W

Power supply type: single-phase 220V

Average power consumption: 1.5 kW

Shielding gas: nitrogen or argon

Maximum oxygen content: 0.1%

Cooling method: liquid cooling, chiller included

Substrate clamping method: magnetic clamping

Scanning head speed: 0-10 m/s

Dimensional accuracy: ±0.05 mm

Nesting: automatic nesting with pre-planned path optimization

Supports continuous printing after a power outage: Yes

Available alloys: stainless steel, titanium alloy, tool steel, high-entropy alloy, cobalt-chromium alloy, aluminum alloy, copper alloy

Powder tank capacity: 2.5 L

Supports automatic shutdown: Yes

Filter lifespan: permanent filter, lifespan no less than 30,000 hours

-

Excellent print quality

-

Simple and easy to use interface

-

Supports layer thicknesses up to 150 microns